Digitalization of product development of high strategic relevance

Focus on innovative materials in terms of performance and sustainability

Capsule collections and collabs to drive excitement among BOSS and HUGO

At HUGO BOSS, we put strong efforts on developing collections and products that meet the highest customer demands in terms of design and quality, as well as innovation and sustainability. These requirements are firmly embedded in our strategic claim “Product is Key,” which puts consumers and our products at the center of everything we do. As part of our “CLAIM 5” strategy, we aim to further optimize the price-value proposition to guarantee highest quality, a superior degree of innovation and sustainability, and features that enable our brands to clearly distinguish themselves from the competition. The potential of digitalization is to be fully exploited throughout the entire product development process. Inspiring capsule collections and high-impact collaborations with well-known brands and personalities are also intended to spur the relevance of BOSS and HUGO while driving excitement among both brands. Group Strategy, “Product is Key”

The design and product development process at HUGO BOSS involves the transformation of a creative idea into a commercial product. The work is carried out at our three development centers in Metzingen (Germany), Coldrerio (Switzerland), and Morrovalle (Italy). While the majority of our collections are developed at the Group headquarters in Metzingen, the Coldrerio site is mainly responsible for the development of the product categories shirts, knitwear, shoes and accessories, as well as bodywear and hosiery. In Morrovalle, we develop high-quality shoes and leather accessories.

Product development process

Product development process at HUGO BOSS

The product development process starts with a creative idea, constantly considering customer expectations. Our collections are centered around brand strategy, brand values, as well as global mega and fashion trends. To ensure a holistic brand message, collection and brand communication are closely aligned right from the start of the development process. The transformation of the creative idea and designs into specific collections also takes into account sell-through rates of previous collections as well as feedback gathered from wholesale partners and consumers alike. In the conventional product development process, the second step sees our design teams’ creative ideas tailored in the pattern design phase. Technical product development then turns the models into prototypes and tests their suitability for the industrial production process. In conventional product development, the prototyping is followed by the manufacture of sample collections to ensure that the products meet our high standards in terms of quality and fit. Once production has been completed, the collections are ready to be sold via the respective distribution channels. While historically all the more relevant, the conventional product development process has become less important in recent years, as we have been able to successfully drive digitalization in this area.

>90%

digitally developed

products

by 2025

The digitalization of product development is of high strategic importance to HUGO BOSS. In line with our strategic claim “Lead in Digital,” we have set ourselves the goal of developing more than 90% of our products digitally by 2025. Thanks to further important progress made in the evolution of immersive 3D simulations and the expansion of digital development to additional product groups over the past few years, we were able to further increase the proportion of digitally developed products to around 65% in fiscal year 2023 (2022: around 55%). Already today, we are able to run the entire product development process digitally. One prime example in this regard will be our capsule collection Aston Martin x BOSS as part of the exclusive BOSS Camel brand line. Set to launch in the second half of 2024, it will be developed digitally – from first sketches and the selection of materials to the distribution of the styles via our digital channels. Overall, digital workflows allow us to operate more flexibly throughout the entire value chain, shorten lead times, and consequently adapt more effectively and quickly to changes in consumer trends and customer demand. In addition, the digitally developed styles are also used in distribution – for example, when selling our collections to wholesalers via digital showrooms or via “virtual try-on” to our end-customers on hugoboss.com. At the same time, we are convinced that the ongoing digitalization of our product development process will also contribute positively to our sustainability ambitions, as it allows for predicting trends more accurately, better anticipating customer preferences, and further reducing the need for physical samples, thus minimizing waste and reducing our CO2 emissions. Sustainability

In order to remain at the forefront of rapidly evolving technologies in digital product development, HUGO BOSS continuously invests in strengthening the expertise of its employees. Already today, thanks to our strong expertise in the field of digital product development, dedicated trainings for further increasing 3D competence are conducted in-house, fostering a true digital mindset with an end-to-end understanding of all relevant digital processes. To further expand knowledge with regards to 3D design, additional trainings were introduced in 2023 while the Company also hosted internal events to strengthen the knowledge exchange among employees. On top of that, we further strengthened our expertise and innovation capabilities by setting up a dedicated 3D design team, implementing innovative software solutions while adapting knowledge from the gaming world, among other things.

HELLO Brands

To become one of the top 100 global brands, we pour all our passion into driving brand relevance for BOSS and HUGO with innovative marketing and product initiatives.

Learn more Learn moreKey areas of product innovation

As part of our “CLAIM 5” growth strategy, we are committed to unlocking the full potential of BOSS and HUGO by perfectly dressing our customers 24/7 and for every occasion. Driving casualization along our collections and further optimizing wearing comfort through the increased use of innovative materials are of particular importance and thus a key area of production innovation at HUGO BOSS. With BOSS, we continue to drive innovation, particularly with our athleisurewear offering as part of BOSS Green. In 2023, putting strong emphasis on dressing consumers for an active lifestyle, we launched selected functional capsule collections, for example in tennis with brand ambassador Matteo Berrettini, while also introducing a new highly functional collection with runner Alica Schmidt as part of BOSS Womenswear. To further elevate the wearing comfort within our BOSS formalwear assortment, already in 2022 we introduced the BOSS Performance product range, which combines formalwear outfits with sportswear elements, thereby perfectly matching the needs of our customers. It ranges from super-stretchable and machine-washable styles to lightweight and wrinkle-free products that can be easily carried in hand luggage. In 2023, we further expanded the performance product range to BOSS Womenswear, while, at the same time, further implementing performance functionalities into our existing product range as part of BOSS Menswear, making use of the experience gained in prior years. This includes, for example, tech-linen or tech-flannel suits, made of performance stretch material thus offering increased levels of comfort. On top of that, we expanded our product portfolio by introducing HUGO BLUE in early 2024, a new line under the HUGO brand. With a clear focus on denimwear, HUGO BLUE is particularly dedicated to leveraging the full potential of the HUGO brand, with jersey, knitwear, outerwear pieces, and accessories completing the offering. Group Strategy, “Product is Key”

We are fully committed to living up to growing customer expectations in terms of sustainability. To this end, we increasingly rely on innovative, sustainable materials, and manufacturing techniques in the development of our collections. As part of our long-term strategic partnership with HeiQ AeoniQ, we are focusing on the joint development and production of a sustainable, circular, and recyclable cellulose yarn with the aim of replacing environmentally harmful polyester and nylon. In this context, we successfully launched the first two BOSS polo shirts made of almost 90% AeoniQ together with BOSS brand ambassador Matteo Berrettini in the first half of 2023, which were recognized with the 2023 ISPO Award for setting new standards in the field of more sustainable performance apparel. Later that year, three additional outerwear styles crafted in AeoniQ fabric formed a limited-edition capsule collection, which was made available with the BOSS Milan Fashion Show in September. On top of that, as part of our “BETTER BOSS” initiative, which unites our circularity ambitions and our goal of creating 60% of our products from lower-impact materials by 2025, we launched a fully circular capsule collection in late 2023, made from recycled textiles and thus extending the product lifetime. A particular highlight within this was three all-gender pieces crafted exclusively from recycled wool. Also at HUGO, we strive to maximize our positive impact as part of our sustainability ambitions, particularly within our “WE ACT” product range. This covers products made from at least 60% more sustainable raw materials such as regenerative cotton. Going forward, leveraging such initiatives is set to support our goal of enabling 80% of BOSS and HUGO products to become circular by 2030. The latter is also firmly anchored in our sustainability strategy, which contains a strong commitment to “Increase Circularity.” Sustainability

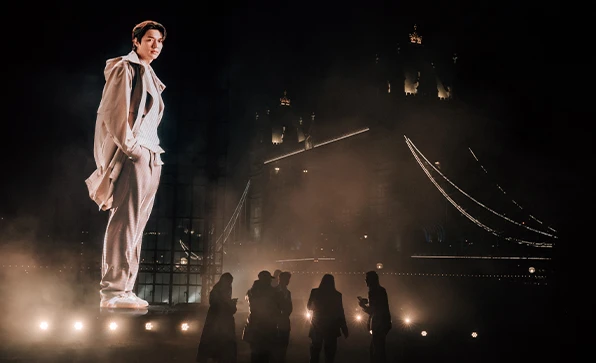

The four main collections of BOSS and HUGO are designed to offer customers both a broad range of core products as well as a variety of seasonal and particularly fashion-conscious styles. Besides these main collections, we team up with other well-known brands and personalities to create inspiring capsule collections and high-impact collaborations. In doing so, we want to constantly increase the relevance of BOSS and HUGO and excite consumers all over the globe. In 2023, BOSS launched several capsules together with its brand ambassadors, as well as with strong partners including Porsche, Samsonite, and the American football league NFL. Fiscal year 2023 also saw the development of a dedicated BOSS Womenswear capsule with British supermodel Naomi Campbell, which will be launched in early 2024 and comprises styles from versatile outerwear to cozy sweatshirts. HUGO, on the other hand, teamed up with audio lifestyle company Urbanista and brand ambassador and TikTok superstar Bella Poarch, among others. Exceptional collaborations like these will continue to play a key role in attracting new and younger consumers and fully unlocking the great potential of both brands in the future. Group Strategy, “Product is Key”

Key R&D figures

The research and product development (R&D) departments of HUGO BOSS are staffed primarily by fashion and 3D designers, tailors, shoe and clothing technicians, and engineers. As of December 31, 2023, the number of employees in this area totaled 751 (2022: 656).

Research and product development expenses

In line with our strategic claims “Product is Key” and “Organize for Growth,” our R&D expenses grew 11% to EUR 89 million in 2023, with the majority of the increase mainly resulting from an increase in personnel expenses. At 71%, personnel expenses continued to account for the majority of R&D expenses last fiscal year (2022: 71%). The remainder is primarily composed of other department expenses. In 2023, R&D costs were again mostly recognized as expenses at the time they were incurred. In addition, production-related development expenses are included in the cost of conversion of inventories. No development expenses were recognized as internally generated intangible assets due to the predominantly short product life cycles.